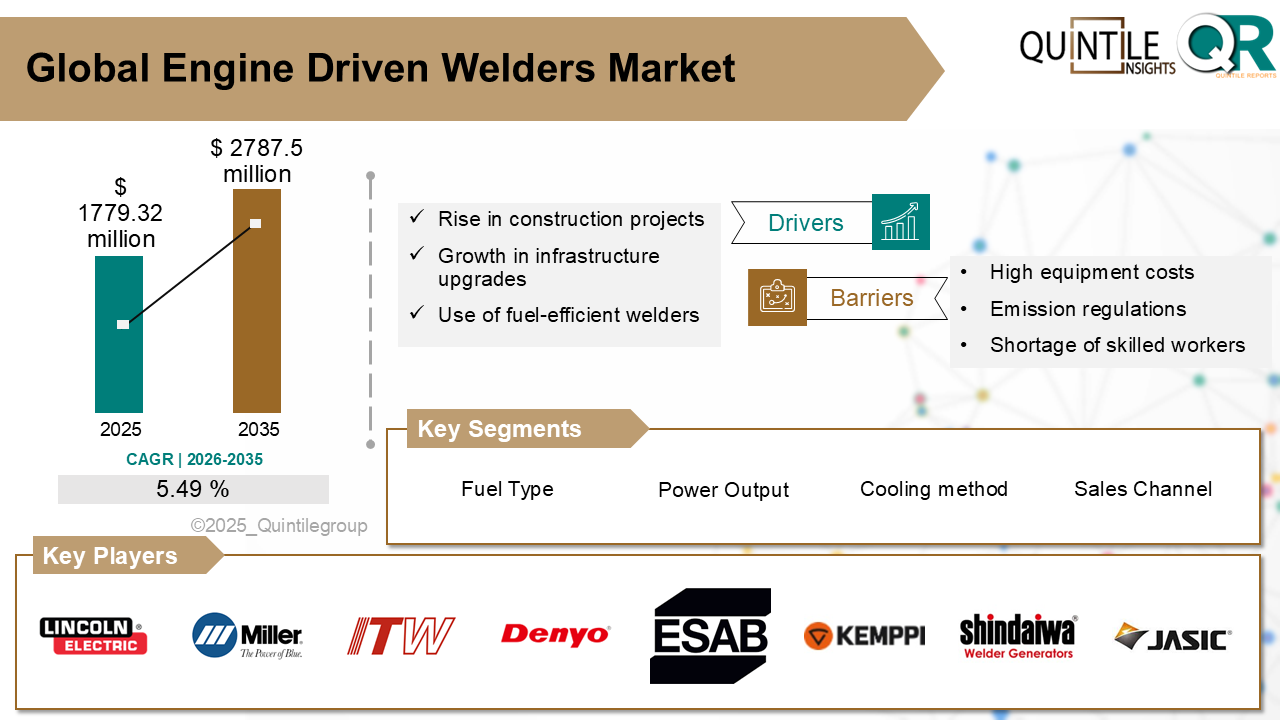

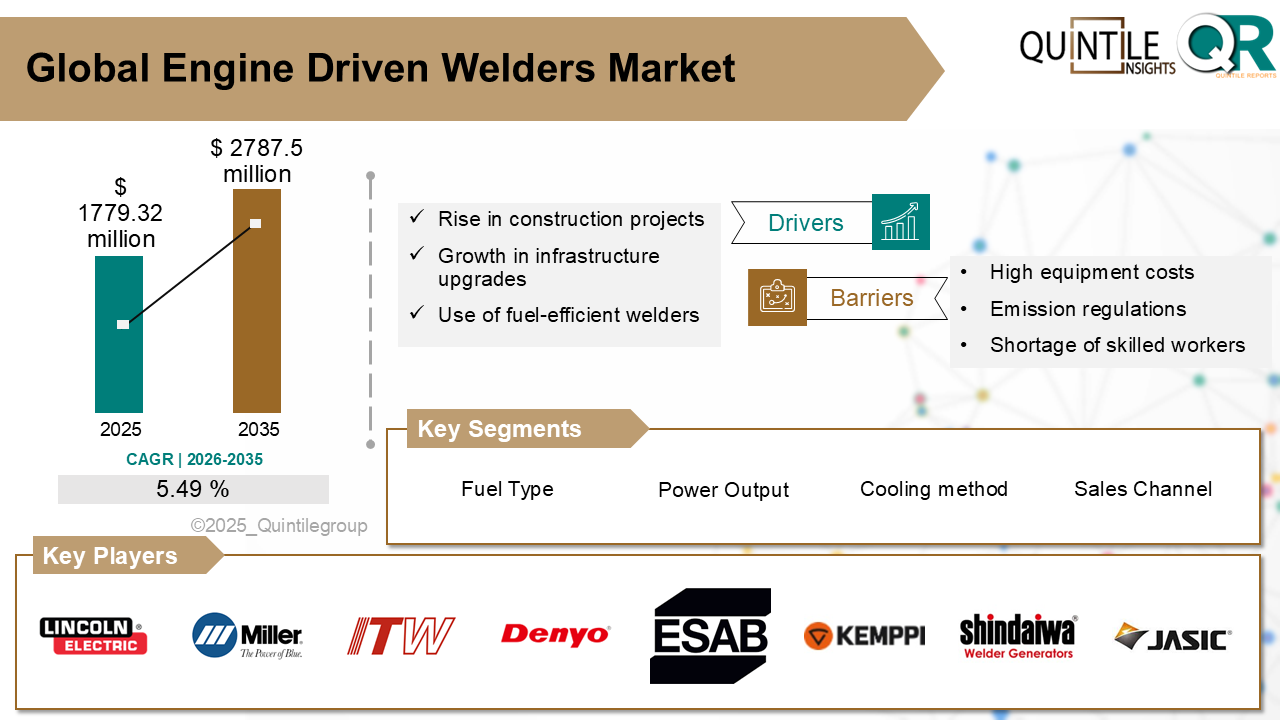

The Global Engine Driven Welders Market was estimated at USD 1779.32 million in 2025 and is projected to reach USD 2787.5 million by 2035, reflecting a robust CAGR of 5.49% over the forecast period from 2026 to 2035. The Engine Driven Welders market report offers a comprehensive and nuanced view of the industry, moving beyond conventional analysis. It provides a thorough examination of the markets dynamics, encompassing a detailed exploration of the factors propelling growth, such as evolving economic conditions, advancements in technology, shifts in regulatory policies, and changes in consumer behavior. Furthermore, the report discusses the projected Compound Annual Growth Rate (CAGR), providing stakeholders with a clear understanding of the market's expected growth trajectory and offering data-driven insights into future market dynamics.

The Engine Driven Welders market under analysis is characterized by dynamic growth and evolving trends that are reshaping the competitive landscape. With 2025 serving as the base year for this Engine Driven Welders market study, recent data highlights a significant expansion driven by technological advancements, rising consumer demand, and a growing focus on innovation. Companies are refining their go-to-market (GTM) strategies to effectively capture these emerging opportunities and respond to the rapidly changing market dynamics.

Key trends influencing the Engine Driven Welders market include the rapid adoption of digital technologies, the integration of sustainable practices, and the increasing importance of customer experience. These trends are not only driving growth but also creating new challenges for industry participants, who must adapt their GTM strategies to navigate regulatory changes, supply chain disruptions, and fluctuating economic conditions. Despite these challenges, the Engine Driven Welders market is poised for sustained growth, with emerging markets playing a critical role in the expansion of the industry.

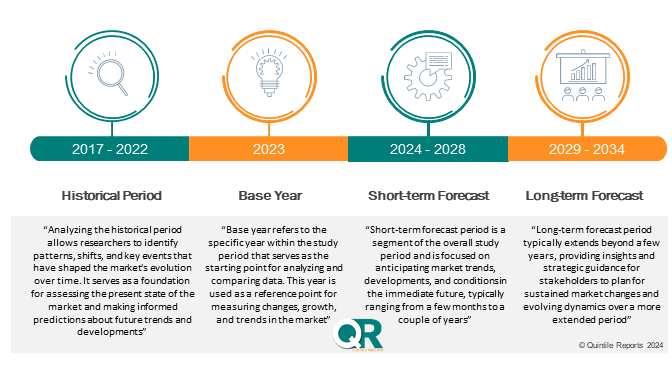

Looking ahead, the Engine Driven Welders market is forecasted to continue its upward momentum through 2035, supported by ongoing investments in research and development, strategic partnerships, and mergers and acquisitions. Companies that can effectively tailor their GTM strategies to the evolving market landscape, innovate, and meet shifting consumer demands are likely to achieve sustained success. Engine Driven Welders market report provides a comprehensive analysis of the current market environment and offers valuable insights into the key drivers, challenges, and opportunities that will shape the industry's future over the next decade. This report offers a comprehensive analysis of market dynamics across various segments, regions, and countries, incorporating both qualitative and quantitative data. It covers the period from 2017 to 2035, providing a detailed examination of historical performance, current market conditions, and future projections.

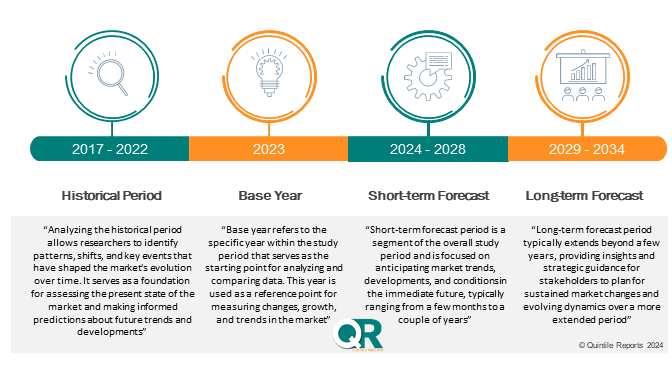

Historical Analysis (2017-2024): The report presents a thorough review of market trends, performance metrics, and growth trajectories for the years 2017 through 2024. This historical perspective is crucial for understanding past market behavior and identifying patterns that influence current and future market dynamics.

Forecast and Projections (2026-2035) : Building on historical data, the report provides forward-looking insights, including market forecasts and growth projections from 2026 to 2035. It details anticipated market trends, emerging opportunities, and potential challenges across different segments, regions, and countries.

Compound Annual Growth Rate (CAGR): The report includes a precise calculation of the compound annual growth rate (CAGR) for the forecast period of 2026 to 2035. This metric will be instrumental in assessing the expected growth trajectory and the overall market potential during the forecast period.

Engine-Driven Welders Market

The engine-driven welders market encompasses portable welding machines that integrate an internal combustion engine, typically gasoline, diesel, or LPG as their power source, enabling use in environments without access to grid electricity. These welders generate the electrical power required for arc welding processes (e.g., stick, MIG, TIG) via an engine-powered generator, making them indispensable for remote, outdoor, or emergency operation sites such as construction zones, pipeline projects, mining operations, and farm or ranch maintenance activities.

The global market for engine-driven welders is substantial and steadily expanding due to ongoing infrastructure development, heightened demand for on-site fabrication and maintenance in sectors like construction, oil & gas, shipbuilding, and agriculture, and technological advancements to improve fuel efficiency and emission reduction.

What are the drivers of the engine-driven welders marketRapid expansion of infrastructure including roads, bridges, and remote construction projects drives demand for portable welding solutions not reliant on grid power.

Operations in oil & gas, mining, and pipeline construction frequently occur off-grid, increasing the need for reliable, rugged welders powered by onboard engines.

Industrial repair, maintenance, and shipbuilding rely heavily on mobile, durable welding equipment, fuelling consistent market growth.

The other fundamental driver is sustainability. As environmental awareness rises, manufacturers shift toward environmentally friendly and biodegradable materials for associated components such as carrier rings.

Advancements in inverter controls, digital interfaces, hybrid/battery-powered engines, and fuel-efficient, low-emission systems are strengthening the adoption of engine-driven welders.

Growing integration of IoT, remote monitoring, automated controls, and hybrid systems simplifies operations and enhances productivity, especially on remote or hazardous sites.

What are the challenges and restraining factors of the engine-driven welders marketEngine-powered welders require regular maintenance of engines, oil, and fuel. High maintenance costs become a burden for small contractors and discourage adoption in cost-sensitive markets.

Strict emissions regulations (EPA Tier 4, EU Stage V) and noise restrictions limit the use of gasoline- or diesel-powered equipment in urban or environmentally protected areas.

Large size and heavy weight limit portability. Many units must be transported via trailers, reducing usability in constrained or hard-to-reach environments compared to modern inverter-based electric welders.

Advancements in battery-powered or inverter-based welding machines provide lightweight, greener alternatives, which can reduce demand for engine-driven units over time.

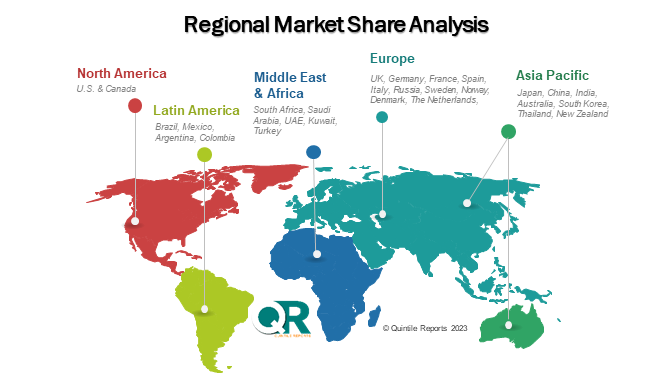

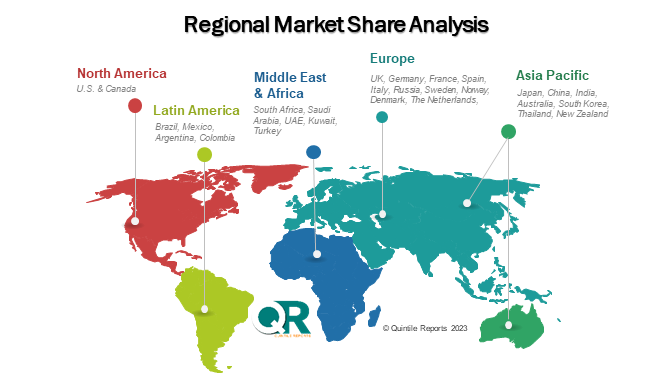

What are the regional trends of the engine-driven welders marketNorth America leads the market due to robust manufacturing, construction, and pipeline maintenance activities. The region's infrastructure and remote-site needs favour powerful mobile welding units. Manufacturers are integrating fuel-efficient engines, remote monitoring, hybrid generator-welder combos, and enhanced electronics to meet regulatory standards.

Europe is driven by automotive, shipbuilding, and high-precision construction sectors. Strict emission laws encourage adoption of low-emission diesel engines, inverter-integrated welders, and smart diagnostic systems. Germany, France, and the UK are key innovation hubs.

Asia-Pacific is the fastest-growing region. Rapid industrialization, infrastructure megaprojects, and manufacturing expansion in China, India, and Southeast Asia drive demand for compact, versatile diesel and gasoline engine-driven welders. Dual-fuel and eco-engine models are gaining traction.

Latin America shows steady demand due to construction, pipeline repairs, and agricultural development. Brazil and Mexico are adopting efficient, low-maintenance diesel welding units to support field operations.

Middle East & Africa see rising adoption driven by oil & gas, mining, and large-scale infrastructure. Demand centers on rugged, low-emission welders with remote start and integrated generator features for harsh environments.

Country-Wise OutlookU.S. Technological Convenience and Ageing Population Drive the Market:

The U.S. dominates the electric-start generator market due to weather-related outages and high demand for convenient, low-effort power solutions. An aging population boosts adoption of push-button and remote-start systems. Disaster-prone states like Texas, Florida, and California drive strong demand for portable, smart-enabled models.

Growth in smart home and IoT ecosystems supports the development of Bluetooth-enabled, auto-choke, and self-diagnostic generator-welders as part of larger trends prioritizing convenience and reliability.

Germany Renewable Energy Infrastructure Drives Demand:

Germanys Energiewende has created strong demand for engine-driven welders to support installation and maintenance of wind turbines, solar farms, and hydrogen pipelines often located off-grid.

Modern German-engineered welders incorporate low-emission diesel or hybrid engines, advanced inverter systems, and multi-process capabilities that comply with strict environmental standards.

Germanys push into green hydrogen further increases demand for welders meeting high-precision, high-duty cycle requirements with digital controls and real-time diagnostics.

Japan Infrastructure Modernisation Boosts Demand:

Japans aging infrastructure drives demand for portable, high-capacity engine-driven welders. Projects under the "National Resilience Plan" focus heavily on rural, mountainous, or disaster-affected regions where grid access is limited.

Demand is rising for multi-process, compact, fuel-efficient welders capable of performing in diverse field conditions. Japan also emphasizes safety and automation, prompting designs featuring low-noise engines, auto-idle, and smart monitoring systems.

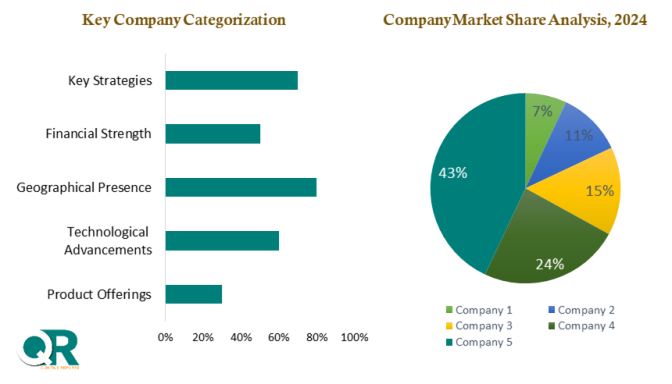

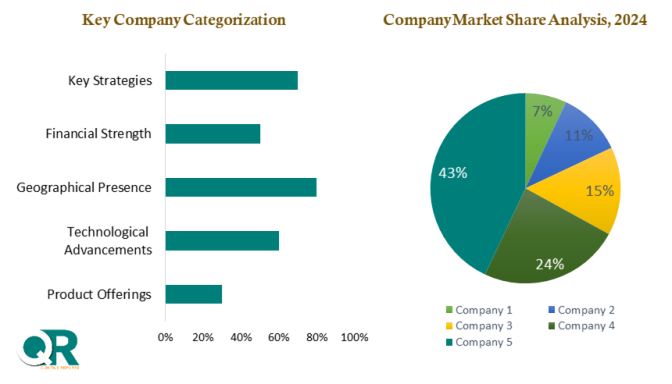

Competitive AnalysisCompetition centers on innovation, fuel efficiency, emission reduction, and operator convenience. Key players such as Miller Electric, Lincoln Electric, and ESAB are launching hybrid and inverter-based engine-driven welders with improved electronics and remote control options.

Manufacturers are investing in cleaner engine technologies to comply with EPA, CARB, and EU regulations. They are also exploring alternative fuels such as CNG, LPG, and biofuels.

To meet rising demand, companies are adopting modular manufacturing, automated assembly, localized production, and advanced supply chains, enabling faster delivery and high-volume output.

Brands compete on convenience with CO-reducing technology, ergonomic designs, wireless start systems, and predictive maintenance services. Equipment-as-a-service models are increasingly becoming norm in the rental and contractor segments.

Key players include: Lincoln Electric Holdings, Inc., Miller Electric Mfg. LLC (ITW Welding), Denyo Co., Ltd., ESAB (Colfax Corporation), KEMPPI Oy, Shindaiwa Ltd., Panasonic Welding Systems Co., Ltd., KOIKE ARONSON, INC., Cruxweld Industrial Equipments Pvt. Ltd., Mosa S.p.A., Genset S.p.A., ZENA, Inc., RILAND, Ador Welding Ltd., Jasic Technology Co., Ltd.

Recent DevelopmentIn February 2025, Lincoln Electric introduced the Ranger Air 330MPX, an all-in-one engine-driven welder with an integrated rotary-screw air compressor (30 CFM), auxiliary power, and battery charging.

In March 2025, Miller Electric launched the HDI 265 Air Pak and HDI 325 Air Pak, its first hydraulically driven all-in-one welders. These units combine welding, compressed air, auxiliary power, and battery crank/charge, reducing equipment footprint by 54% and saving up to 400 lb of space on work trucks.

Our team of experienced researchers has meticulously gathered and analyzed data to deliver a thorough examination of market dynamics, competitive landscape, and emerging technologies. With a focus on delivering actionable intelligence, this report aims to empower decision-makers with the information needed to make informed choices and stay ahead of the competition. Whether you are a seasoned industry player or a new entrant, our market research report serves as a strategic tool to navigate the complexities of the market, aiding in successful business planning and growth strategies.

This chapter of our Engine Driven Welders market report provides an in-depth examination of the factors shaping the industry landscape. This section typically encompasses several key elements to offer a comprehensive understanding of the industry landscape such as market drivers & restraints analysis, market opportunities & trend analysis, market size & growth analysis, competitive analysis, SWOT analysis, business environment tools such as Porter's five forces & PESTEL analysis, Ansoff Matrix analysis, penetration & growth prospect analysis, regulatory framework & reimbursement scenario analysis, impact of macro & micro economic factors analysis such as Covid-19 impact, GDP growth, market inflation, U.S.- China trade war, Russia-Ukraine war impact, and supply chain analysis.

The segment analysis chapter of Engine Driven Welders market report is a critical section that delves into a detailed examination of the market's various segments. Segmentation involves dividing the market into distinct categories based on certain criteria to better understand and address the diverse needs of consumers. This chapter typically follows the introduction and provides a more granular view of the market, offering valuable insights for businesses and stakeholders. The components of the chapter lude segment definitions to understand the inclusions and exclusions of the study, assumptions, market size estimates and growth trend analysis of each segment, qualitative analysis of the segment, technological advancements, market penetration rate, market adoption rate, market share examination by each segment, segment growth drivers and restraint barriers, consumer behaviour and challenge analysis.

The chapter in Engine Driven Welders market research report is a pivotal section that examines and predicts the market dynamics and trends specific to different geographical regions. This chapter is crucial for businesses and stakeholders seeking a comprehensive understanding of how the market behaves across various locations, enabling them to tailor strategies and make informed decisions based on regional variations. The regional analysis chapter of our Engine Driven Welders market report is classified into regions & country-level. The chapter consists of North America (U.S., Canada), Europe (UK, Germany, France, Italy, Spain, Russia, Sweden, Denmark, Norway, Rest of Europe), Asia Pacific (Japan, China, India, Australia, South Korea, Thailand, Rest of Asia Pacific), Latin America (Brazil, Mexico, Argentina, Colombia, Rest of Latin America), Middle East & Africa (South Africa, Saudi Arabia, UAE, Kuwait, Rest of Middle East & Africa).

This section of a Engine Driven Welders market report is a crucial segment that provides a comprehensive overview of the competitive landscape within the market. This section is vital for businesses, investors, and stakeholders seeking insights into key players, their market positioning, strengths, weaknesses, strategies, and potential impacts on the overall market dynamics. The chapter includes research methodology used to analyse the market competition, list of key players operating in the market, detailed company profile section which includes company overview, business verticals, financial performance, product/services benchmarking, geographical presence, and strategic initiatives.

| Report Scope | Details |

| Report Version | 2026 |

| Growth Rate | CAGR of 5.49 from 2026 to 2035 |

| Base year | 2025 |

| Actual estimates/Historical data | 2017 - 2024 |

| Forecast period | 2026 - 2035 |

| Quantitative units | Revenue in USD million/billion & CAGR from 2026 to 2035 |

| Country scope | North America (U.S., Canada), Europe (UK, Germany, France, Italy, Spain, Russia, Sweden, Denmark, Norway, Rest of Europe), Asia Pacific (Japan, China, India, Australia, South Korea, Thailand, Rest of Asia Pacific), Latin America (Brazil, Mexico, Argentina, Colombia, Rest of Latin America), Middle East & Africa (South Africa, Saudi Arabia, UAE, Kuwait, Rest of Middle East & Africa). |

| The Segment covered by Fuel Type |

|

| The Segment covered by Power Output |

|

| Companies covered |

|

| Report coverage | Revenue forecast, company share, competitive landscape, growth factors, and trends |

| Free customization scope (equivalent to 5 analyst working days) | If you need specific information, which is not currently within the scope of the report, we will provide it to you as a part of the customization |

Statistics for the 2025 Engine Driven Welders market share, size, and revenue growth rate were created by Quintile Report™. Engine Driven Welders analysis includes a market forecast outlook for 2035 and a historical overview. Get a free PDF sample of this market analysis, please get in touch with our principal analyst at sales@quintilereports.com

List of Tables

Table 1 List of Abbreviation and acronyms

Table 2 List of Sources

Table 3 North America Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 4 North America Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 5 U.S. Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 6 Canada Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 7 Europe Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 8 Europe Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 9 Germany Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 10 U.K. Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 11 France Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 12 Italy Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 13 Spain Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 14 Sweden Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 15 Denmark Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 16 Norway Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 17 The Netherlands Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 18 Russia Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 19 Asia Pacific Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 20 Asia Pacific Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 21 China Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 22 Japan Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 23 India Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 24 Australia Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 25 South Korea Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 26 Thailand Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 27 Latin America Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 28 Latin America Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 29 Brazil Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 30 Mexico Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 31 Argentina Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 32 Middle East and Africa Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 33 Middle East and Africa Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 34 South Africa Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 35 Saudi Arabia Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 36 UAE Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 37 Kuwait Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 38 Turkey Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Fig.1 Market research process

Fig.2 Market research approaches

Fig.3 Global Engine Driven Welders Market: market scenario

Fig.4 Global Engine Driven Welders Market competitive outlook

Fig.5 Global Engine Driven Welders Market driver analysis

Fig.6 Global Engine Driven Welders Market restraint analysis

Fig.7 Global Engine Driven Welders Market opportunity analysis

Fig.8 Global Engine Driven Welders Market trends analysis

Fig.9 Global Engine Driven Welders Market: Segment Analysis (Based on the scope)

Fig.10 Global Engine Driven Welders Market: regional analysis

Fig.11 Global market shares and leading market players

Fig.12 North America market share and leading players

Fig.13 Europe market share and leading players

Fig.14 Asia Pacific market share and leading players

Fig.15 Latin America market share and leading players

Fig.16 Middle East & Africa market share and leading players

Fig.17 North America, by country

Fig.18 North America

Fig.19 North America market estimates and forecast, 2017-2035

Fig.20 U.S.

Fig.21 Canada

Fig.22 Europe

Fig.23 Europe market estimates and forecast, 2017-2035

Fig.24 U.K.

Fig.25 Germany

Fig.26 France

Fig.27 Italy

Fig.28 Spain

Fig.29 Sweden

Fig.30 Denmark

Fig.31 Norway

Fig.32 The Netherlands

Fig.33 Russia

Fig.34 Asia Pacific

Fig.35 Asia Pacific market estimates and forecast, 2017-2035

Fig.36 China

Fig.37 Japan

Fig.38 India

Fig.39 Australia

Fig.40 South Korea

Fig.41 Thailand

Fig.42 Latin America

Fig.43 Latin America market estimates and forecast, 2017-2035

Fig.44 Brazil

Fig.45 Mexico

Fig.46 Argentina

Fig.47 Colombia

Fig.48 Middle East and Africa

Fig.49 Middle East and Africa market estimates and forecast, 2017-2035

Fig.50 Saudi Arabia

Fig.51 South Africa

Fig.52 UAE

Fig.53 Kuwait

Fig.54 Turkey

The Global Engine Driven Welders Market was estimated at USD 1779.32 million in 2025 and is projected to reach USD 2787.5 million by 2035, reflecting a robust CAGR of 5.49% over the forecast period from 2026 to 2035. The Engine Driven Welders market report offers a comprehensive and nuanced view of the industry, moving beyond conventional analysis. It provides a thorough examination of the markets dynamics, encompassing a detailed exploration of the factors propelling growth, such as evolving economic conditions, advancements in technology, shifts in regulatory policies, and changes in consumer behavior. Furthermore, the report discusses the projected Compound Annual Growth Rate (CAGR), providing stakeholders with a clear understanding of the market's expected growth trajectory and offering data-driven insights into future market dynamics.

The Engine Driven Welders market under analysis is characterized by dynamic growth and evolving trends that are reshaping the competitive landscape. With 2025 serving as the base year for this Engine Driven Welders market study, recent data highlights a significant expansion driven by technological advancements, rising consumer demand, and a growing focus on innovation. Companies are refining their go-to-market (GTM) strategies to effectively capture these emerging opportunities and respond to the rapidly changing market dynamics.

Key trends influencing the Engine Driven Welders market include the rapid adoption of digital technologies, the integration of sustainable practices, and the increasing importance of customer experience. These trends are not only driving growth but also creating new challenges for industry participants, who must adapt their GTM strategies to navigate regulatory changes, supply chain disruptions, and fluctuating economic conditions. Despite these challenges, the Engine Driven Welders market is poised for sustained growth, with emerging markets playing a critical role in the expansion of the industry.

Looking ahead, the Engine Driven Welders market is forecasted to continue its upward momentum through 2035, supported by ongoing investments in research and development, strategic partnerships, and mergers and acquisitions. Companies that can effectively tailor their GTM strategies to the evolving market landscape, innovate, and meet shifting consumer demands are likely to achieve sustained success. Engine Driven Welders market report provides a comprehensive analysis of the current market environment and offers valuable insights into the key drivers, challenges, and opportunities that will shape the industry's future over the next decade. This report offers a comprehensive analysis of market dynamics across various segments, regions, and countries, incorporating both qualitative and quantitative data. It covers the period from 2017 to 2035, providing a detailed examination of historical performance, current market conditions, and future projections.

Historical Analysis (2017-2024): The report presents a thorough review of market trends, performance metrics, and growth trajectories for the years 2017 through 2024. This historical perspective is crucial for understanding past market behavior and identifying patterns that influence current and future market dynamics.

Forecast and Projections (2026-2035) : Building on historical data, the report provides forward-looking insights, including market forecasts and growth projections from 2026 to 2035. It details anticipated market trends, emerging opportunities, and potential challenges across different segments, regions, and countries.

Compound Annual Growth Rate (CAGR): The report includes a precise calculation of the compound annual growth rate (CAGR) for the forecast period of 2026 to 2035. This metric will be instrumental in assessing the expected growth trajectory and the overall market potential during the forecast period.

Engine-Driven Welders Market

The engine-driven welders market encompasses portable welding machines that integrate an internal combustion engine, typically gasoline, diesel, or LPG as their power source, enabling use in environments without access to grid electricity. These welders generate the electrical power required for arc welding processes (e.g., stick, MIG, TIG) via an engine-powered generator, making them indispensable for remote, outdoor, or emergency operation sites such as construction zones, pipeline projects, mining operations, and farm or ranch maintenance activities.

The global market for engine-driven welders is substantial and steadily expanding due to ongoing infrastructure development, heightened demand for on-site fabrication and maintenance in sectors like construction, oil & gas, shipbuilding, and agriculture, and technological advancements to improve fuel efficiency and emission reduction.

What are the drivers of the engine-driven welders marketRapid expansion of infrastructure including roads, bridges, and remote construction projects drives demand for portable welding solutions not reliant on grid power.

Operations in oil & gas, mining, and pipeline construction frequently occur off-grid, increasing the need for reliable, rugged welders powered by onboard engines.

Industrial repair, maintenance, and shipbuilding rely heavily on mobile, durable welding equipment, fuelling consistent market growth.

The other fundamental driver is sustainability. As environmental awareness rises, manufacturers shift toward environmentally friendly and biodegradable materials for associated components such as carrier rings.

Advancements in inverter controls, digital interfaces, hybrid/battery-powered engines, and fuel-efficient, low-emission systems are strengthening the adoption of engine-driven welders.

Growing integration of IoT, remote monitoring, automated controls, and hybrid systems simplifies operations and enhances productivity, especially on remote or hazardous sites.

What are the challenges and restraining factors of the engine-driven welders marketEngine-powered welders require regular maintenance of engines, oil, and fuel. High maintenance costs become a burden for small contractors and discourage adoption in cost-sensitive markets.

Strict emissions regulations (EPA Tier 4, EU Stage V) and noise restrictions limit the use of gasoline- or diesel-powered equipment in urban or environmentally protected areas.

Large size and heavy weight limit portability. Many units must be transported via trailers, reducing usability in constrained or hard-to-reach environments compared to modern inverter-based electric welders.

Advancements in battery-powered or inverter-based welding machines provide lightweight, greener alternatives, which can reduce demand for engine-driven units over time.

What are the regional trends of the engine-driven welders marketNorth America leads the market due to robust manufacturing, construction, and pipeline maintenance activities. The region's infrastructure and remote-site needs favour powerful mobile welding units. Manufacturers are integrating fuel-efficient engines, remote monitoring, hybrid generator-welder combos, and enhanced electronics to meet regulatory standards.

Europe is driven by automotive, shipbuilding, and high-precision construction sectors. Strict emission laws encourage adoption of low-emission diesel engines, inverter-integrated welders, and smart diagnostic systems. Germany, France, and the UK are key innovation hubs.

Asia-Pacific is the fastest-growing region. Rapid industrialization, infrastructure megaprojects, and manufacturing expansion in China, India, and Southeast Asia drive demand for compact, versatile diesel and gasoline engine-driven welders. Dual-fuel and eco-engine models are gaining traction.

Latin America shows steady demand due to construction, pipeline repairs, and agricultural development. Brazil and Mexico are adopting efficient, low-maintenance diesel welding units to support field operations.

Middle East & Africa see rising adoption driven by oil & gas, mining, and large-scale infrastructure. Demand centers on rugged, low-emission welders with remote start and integrated generator features for harsh environments.

Country-Wise OutlookU.S. Technological Convenience and Ageing Population Drive the Market:

The U.S. dominates the electric-start generator market due to weather-related outages and high demand for convenient, low-effort power solutions. An aging population boosts adoption of push-button and remote-start systems. Disaster-prone states like Texas, Florida, and California drive strong demand for portable, smart-enabled models.

Growth in smart home and IoT ecosystems supports the development of Bluetooth-enabled, auto-choke, and self-diagnostic generator-welders as part of larger trends prioritizing convenience and reliability.

Germany Renewable Energy Infrastructure Drives Demand:

Germanys Energiewende has created strong demand for engine-driven welders to support installation and maintenance of wind turbines, solar farms, and hydrogen pipelines often located off-grid.

Modern German-engineered welders incorporate low-emission diesel or hybrid engines, advanced inverter systems, and multi-process capabilities that comply with strict environmental standards.

Germanys push into green hydrogen further increases demand for welders meeting high-precision, high-duty cycle requirements with digital controls and real-time diagnostics.

Japan Infrastructure Modernisation Boosts Demand:

Japans aging infrastructure drives demand for portable, high-capacity engine-driven welders. Projects under the "National Resilience Plan" focus heavily on rural, mountainous, or disaster-affected regions where grid access is limited.

Demand is rising for multi-process, compact, fuel-efficient welders capable of performing in diverse field conditions. Japan also emphasizes safety and automation, prompting designs featuring low-noise engines, auto-idle, and smart monitoring systems.

Competitive AnalysisCompetition centers on innovation, fuel efficiency, emission reduction, and operator convenience. Key players such as Miller Electric, Lincoln Electric, and ESAB are launching hybrid and inverter-based engine-driven welders with improved electronics and remote control options.

Manufacturers are investing in cleaner engine technologies to comply with EPA, CARB, and EU regulations. They are also exploring alternative fuels such as CNG, LPG, and biofuels.

To meet rising demand, companies are adopting modular manufacturing, automated assembly, localized production, and advanced supply chains, enabling faster delivery and high-volume output.

Brands compete on convenience with CO-reducing technology, ergonomic designs, wireless start systems, and predictive maintenance services. Equipment-as-a-service models are increasingly becoming norm in the rental and contractor segments.

Key players include: Lincoln Electric Holdings, Inc., Miller Electric Mfg. LLC (ITW Welding), Denyo Co., Ltd., ESAB (Colfax Corporation), KEMPPI Oy, Shindaiwa Ltd., Panasonic Welding Systems Co., Ltd., KOIKE ARONSON, INC., Cruxweld Industrial Equipments Pvt. Ltd., Mosa S.p.A., Genset S.p.A., ZENA, Inc., RILAND, Ador Welding Ltd., Jasic Technology Co., Ltd.

Recent DevelopmentIn February 2025, Lincoln Electric introduced the Ranger Air 330MPX, an all-in-one engine-driven welder with an integrated rotary-screw air compressor (30 CFM), auxiliary power, and battery charging.

In March 2025, Miller Electric launched the HDI 265 Air Pak and HDI 325 Air Pak, its first hydraulically driven all-in-one welders. These units combine welding, compressed air, auxiliary power, and battery crank/charge, reducing equipment footprint by 54% and saving up to 400 lb of space on work trucks.

Our team of experienced researchers has meticulously gathered and analyzed data to deliver a thorough examination of market dynamics, competitive landscape, and emerging technologies. With a focus on delivering actionable intelligence, this report aims to empower decision-makers with the information needed to make informed choices and stay ahead of the competition. Whether you are a seasoned industry player or a new entrant, our market research report serves as a strategic tool to navigate the complexities of the market, aiding in successful business planning and growth strategies.

This chapter of our Engine Driven Welders market report provides an in-depth examination of the factors shaping the industry landscape. This section typically encompasses several key elements to offer a comprehensive understanding of the industry landscape such as market drivers & restraints analysis, market opportunities & trend analysis, market size & growth analysis, competitive analysis, SWOT analysis, business environment tools such as Porter's five forces & PESTEL analysis, Ansoff Matrix analysis, penetration & growth prospect analysis, regulatory framework & reimbursement scenario analysis, impact of macro & micro economic factors analysis such as Covid-19 impact, GDP growth, market inflation, U.S.- China trade war, Russia-Ukraine war impact, and supply chain analysis.

The segment analysis chapter of Engine Driven Welders market report is a critical section that delves into a detailed examination of the market's various segments. Segmentation involves dividing the market into distinct categories based on certain criteria to better understand and address the diverse needs of consumers. This chapter typically follows the introduction and provides a more granular view of the market, offering valuable insights for businesses and stakeholders. The components of the chapter lude segment definitions to understand the inclusions and exclusions of the study, assumptions, market size estimates and growth trend analysis of each segment, qualitative analysis of the segment, technological advancements, market penetration rate, market adoption rate, market share examination by each segment, segment growth drivers and restraint barriers, consumer behaviour and challenge analysis.

The chapter in Engine Driven Welders market research report is a pivotal section that examines and predicts the market dynamics and trends specific to different geographical regions. This chapter is crucial for businesses and stakeholders seeking a comprehensive understanding of how the market behaves across various locations, enabling them to tailor strategies and make informed decisions based on regional variations. The regional analysis chapter of our Engine Driven Welders market report is classified into regions & country-level. The chapter consists of North America (U.S., Canada), Europe (UK, Germany, France, Italy, Spain, Russia, Sweden, Denmark, Norway, Rest of Europe), Asia Pacific (Japan, China, India, Australia, South Korea, Thailand, Rest of Asia Pacific), Latin America (Brazil, Mexico, Argentina, Colombia, Rest of Latin America), Middle East & Africa (South Africa, Saudi Arabia, UAE, Kuwait, Rest of Middle East & Africa).

This section of a Engine Driven Welders market report is a crucial segment that provides a comprehensive overview of the competitive landscape within the market. This section is vital for businesses, investors, and stakeholders seeking insights into key players, their market positioning, strengths, weaknesses, strategies, and potential impacts on the overall market dynamics. The chapter includes research methodology used to analyse the market competition, list of key players operating in the market, detailed company profile section which includes company overview, business verticals, financial performance, product/services benchmarking, geographical presence, and strategic initiatives.

| Report Scope | Details |

| Report Version | 2026 |

| Growth Rate | CAGR of 5.49 from 2026 to 2035 |

| Base year | 2025 |

| Actual estimates/Historical data | 2017 - 2024 |

| Forecast period | 2026 - 2035 |

| Quantitative units | Revenue in USD million/billion & CAGR from 2026 to 2035 |

| Country scope | North America (U.S., Canada), Europe (UK, Germany, France, Italy, Spain, Russia, Sweden, Denmark, Norway, Rest of Europe), Asia Pacific (Japan, China, India, Australia, South Korea, Thailand, Rest of Asia Pacific), Latin America (Brazil, Mexico, Argentina, Colombia, Rest of Latin America), Middle East & Africa (South Africa, Saudi Arabia, UAE, Kuwait, Rest of Middle East & Africa). |

| The Segment covered by Fuel Type |

|

| The Segment covered by Power Output |

|

| Companies covered |

|

| Report coverage | Revenue forecast, company share, competitive landscape, growth factors, and trends |

| Free customization scope (equivalent to 5 analyst working days) | If you need specific information, which is not currently within the scope of the report, we will provide it to you as a part of the customization |

Statistics for the 2025 Engine Driven Welders market share, size, and revenue growth rate were created by Quintile Report™. Engine Driven Welders analysis includes a market forecast outlook for 2035 and a historical overview. Get a free PDF sample of this market analysis, please get in touch with our principal analyst at sales@quintilereports.com

Table 1 List of Abbreviation and acronyms

Table 2 List of Sources

Table 3 North America Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 4 North America Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 5 U.S. Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 6 Canada Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 7 Europe Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 8 Europe Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 9 Germany Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 10 U.K. Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 11 France Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 12 Italy Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 13 Spain Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 14 Sweden Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 15 Denmark Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 16 Norway Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 17 The Netherlands Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 18 Russia Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 19 Asia Pacific Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 20 Asia Pacific Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 21 China Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 22 Japan Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 23 India Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 24 Australia Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 25 South Korea Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 26 Thailand Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 27 Latin America Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 28 Latin America Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 29 Brazil Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 30 Mexico Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 31 Argentina Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 32 Middle East and Africa Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 33 Middle East and Africa Global Engine Driven Welders Market, by Region, (USD Million) 2017-2035

Table 34 South Africa Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 35 Saudi Arabia Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 36 UAE Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 37 Kuwait Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Table 38 Turkey Global Engine Driven Welders Market, by Segment Analysis, (USD Million) 2017-2035

Fig.1 Market research process

Fig.2 Market research approaches

Fig.3 Global Engine Driven Welders Market: market scenario

Fig.4 Global Engine Driven Welders Market competitive outlook

Fig.5 Global Engine Driven Welders Market driver analysis

Fig.6 Global Engine Driven Welders Market restraint analysis

Fig.7 Global Engine Driven Welders Market opportunity analysis

Fig.8 Global Engine Driven Welders Market trends analysis

Fig.9 Global Engine Driven Welders Market: Segment Analysis (Based on the scope)

Fig.10 Global Engine Driven Welders Market: regional analysis

Fig.11 Global market shares and leading market players

Fig.12 North America market share and leading players

Fig.13 Europe market share and leading players

Fig.14 Asia Pacific market share and leading players

Fig.15 Latin America market share and leading players

Fig.16 Middle East & Africa market share and leading players

Fig.17 North America, by country

Fig.18 North America

Fig.19 North America market estimates and forecast, 2017-2035

Fig.20 U.S.

Fig.21 Canada

Fig.22 Europe

Fig.23 Europe market estimates and forecast, 2017-2035

Fig.24 U.K.

Fig.25 Germany

Fig.26 France

Fig.27 Italy

Fig.28 Spain

Fig.29 Sweden

Fig.30 Denmark

Fig.31 Norway

Fig.32 The Netherlands

Fig.33 Russia

Fig.34 Asia Pacific

Fig.35 Asia Pacific market estimates and forecast, 2017-2035

Fig.36 China

Fig.37 Japan

Fig.38 India

Fig.39 Australia

Fig.40 South Korea

Fig.41 Thailand

Fig.42 Latin America

Fig.43 Latin America market estimates and forecast, 2017-2035

Fig.44 Brazil

Fig.45 Mexico

Fig.46 Argentina

Fig.47 Colombia

Fig.48 Middle East and Africa

Fig.49 Middle East and Africa market estimates and forecast, 2017-2035

Fig.50 Saudi Arabia

Fig.51 South Africa

Fig.52 UAE

Fig.53 Kuwait

Fig.54 Turkey

A license granted to one user. Rules or conditions might be applied for e.g. the use of electric files (PDFs) or printings, depending on product.

A license granted to multiple users.

A license granted to a single business site/establishment.

A license granted to all employees within organisation access to the product.

Immediate / Within 24-48 hours - Working days

Online Payments with PayPal and CCavenue

You can order a report by picking any of the payment methods which is bank wire or online payment through any Debit/Credit card or PayPal.

Hard Copy

Report Overview: The Global Gas and Liquid Flow Management Systems Market was valued at USD 21.82 bi

Read MoreReport Overview: The Global Product Fall Protection Systems Market was valued at USD 8.62 million in

Read MoreReport Overview: The Global Superconductor Motors Market was valued at USD 135.82 million in 2025 an

Read More